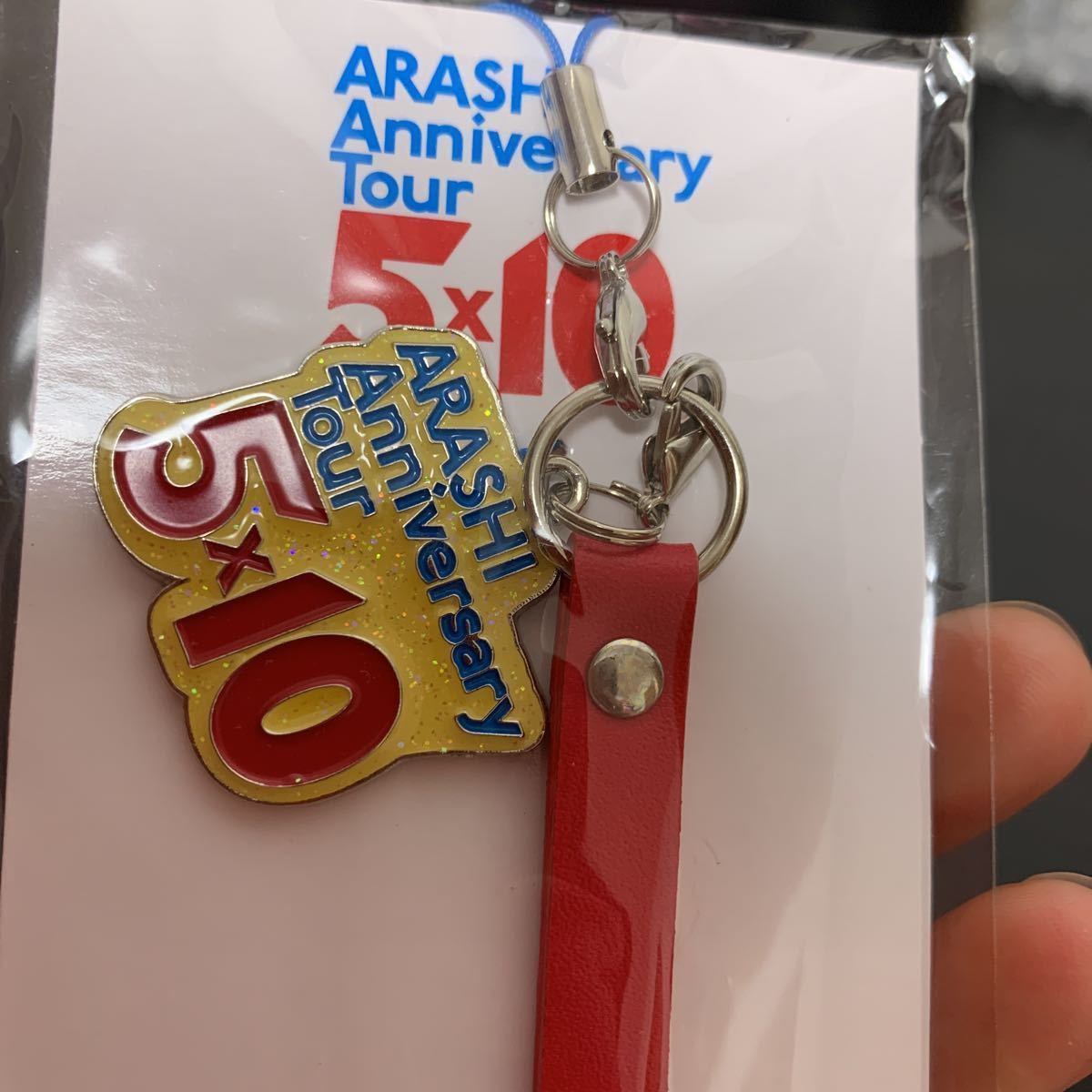

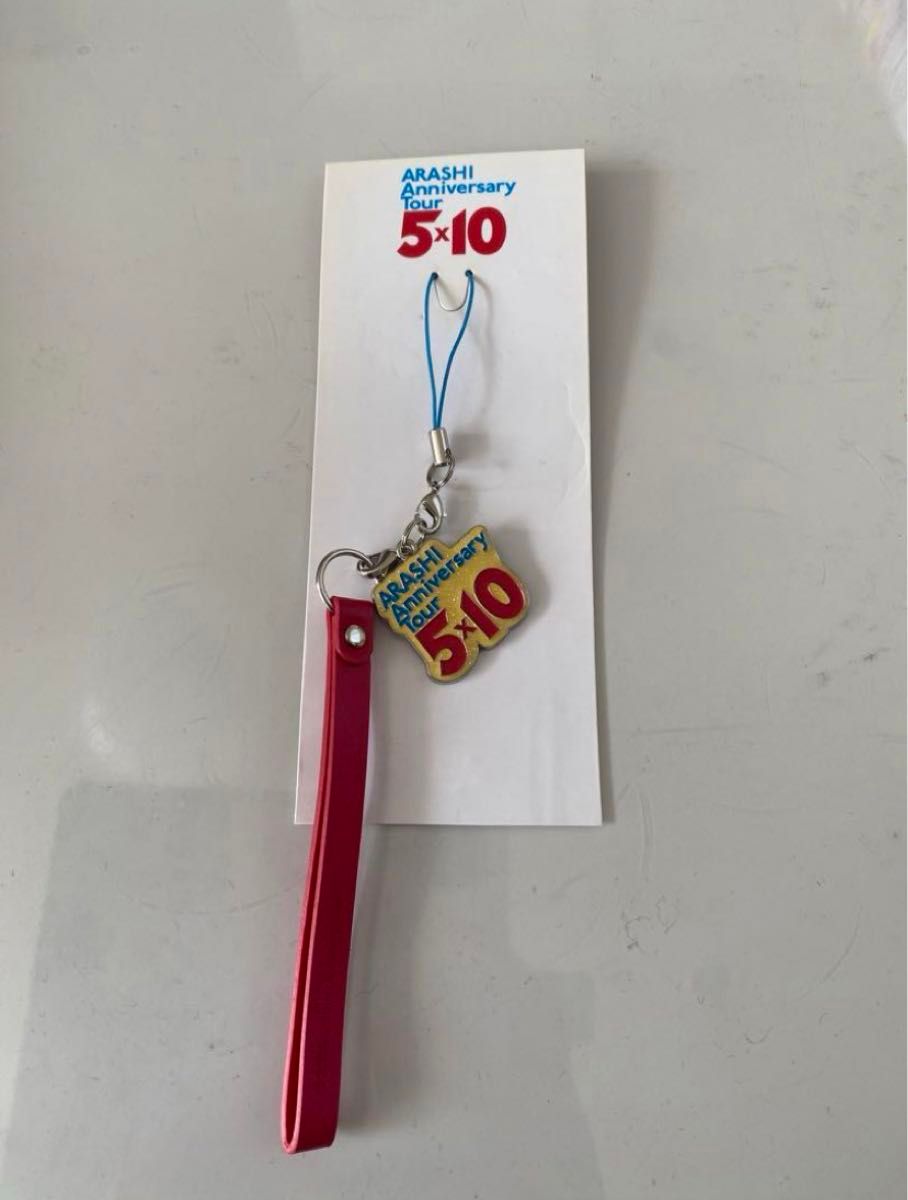

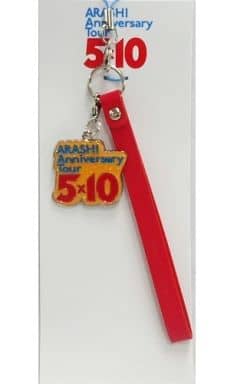

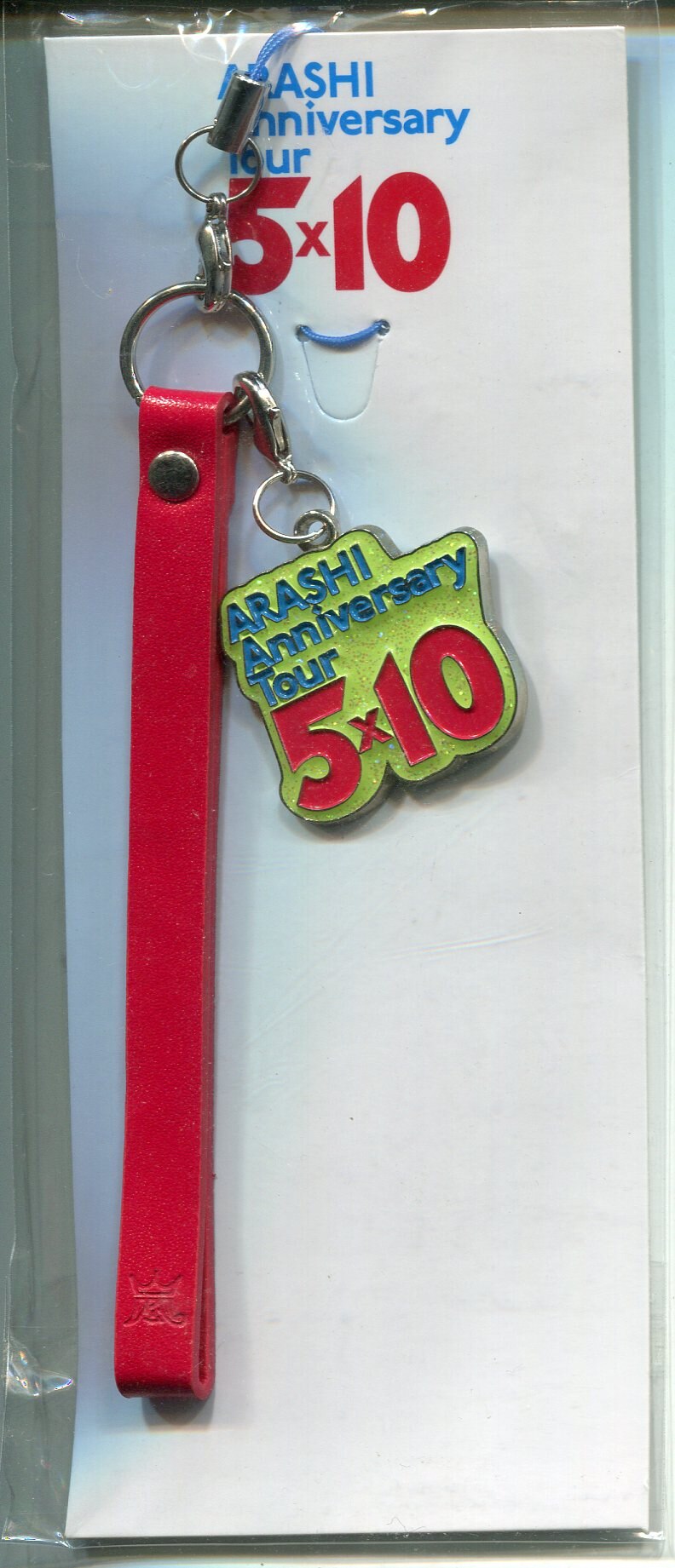

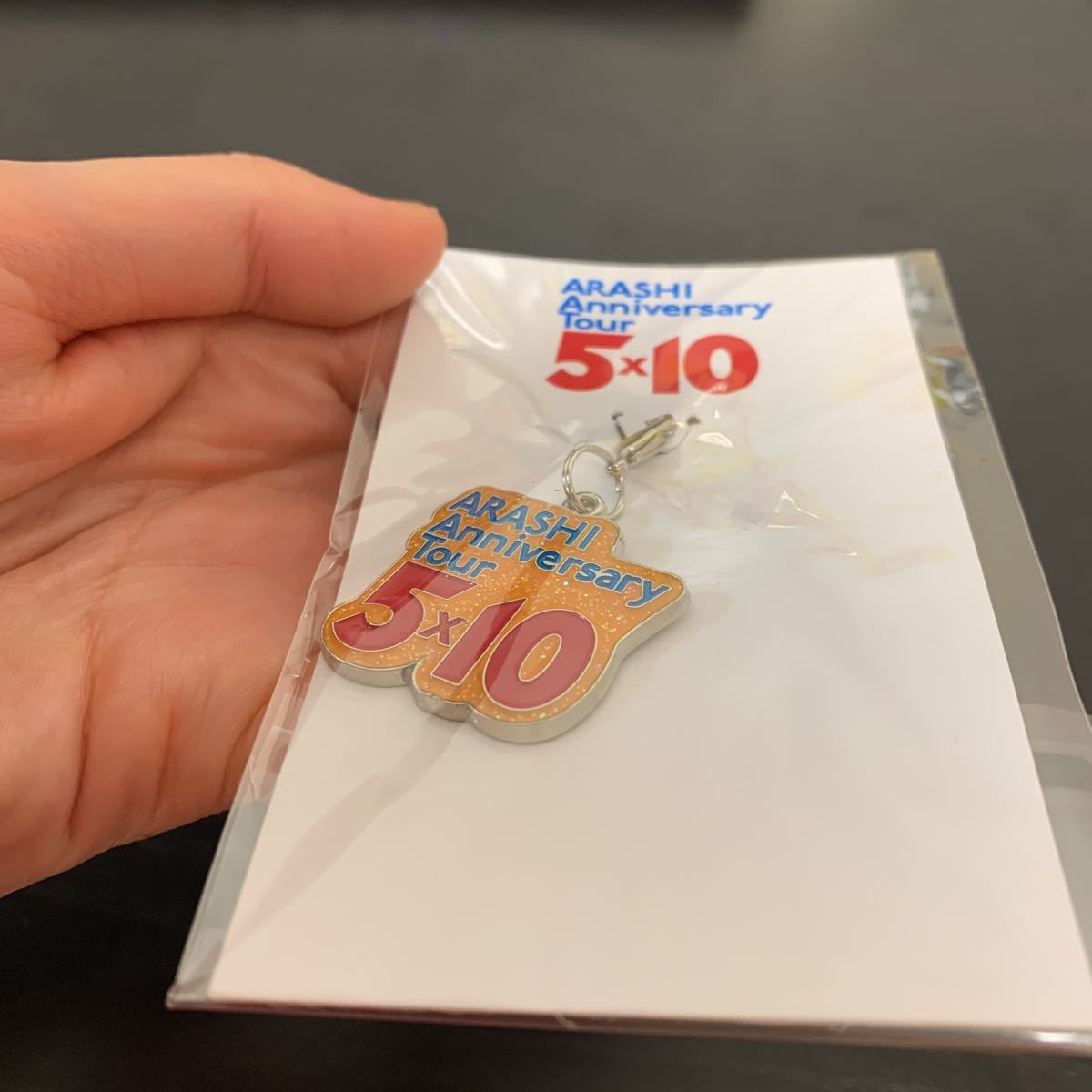

ARASHI 嵐 Anniversary Tour 5x10名古屋限定ストラップ

(税込) 送料込み

商品の説明

ARASHI 嵐 Anniversary Tour 5x10 名古屋限定の携帯ストラップ(オレンジ)です。(新品・未使用)

新品ですので、キズ等はありませんが、そういったことに神経質な方は、入札をご遠慮ください。

配送等に関するクレ-ム、破損、落札後のキャンセル、返品は、お受けできませんので、悪しからずご了承ください。

落札後こちらから連絡をいたしますが、2日以内に連絡をいただけない場合は、「落札者の都合」という事で、

落札を削除させていただきますので、あらかじめご了承ください。

ご質問等ありましたら、連絡ください。

落札後のトラブル防止の為些細な事でも結構ですのでご質問ください。以上宜しくお願いします。商品の情報

| カテゴリー | チケット > 音楽 > 男性アイドル |

|---|---|

| 商品の色を | ホワイト系 / グレイ系 / ブラウン系 |

| 商品の状態 | 新品、未使用 |

嵐 - ARASHI Anniversary Tour 5×10 ストラップ 名古屋の通販 by や

嵐 - ARASHI Anniversary Tour 5×10 ストラップ 名古屋の通販 by や

嵐 - ARASHI Anniversary Tour 5×10 ストラップ 名古屋の通販 by や

嵐 5×10 会場限定販売 チャーム付 ストラップ 名古屋 オレンジ 公式

嵐 - ARASHI Anniversary Tour 5×10 ストラップ 名古屋の通販 by や

嵐 - ARASHI Anniversary Tour 5×10 ストラップ 名古屋の通販 by や

嵐 - ARASHI Anniversary Tour 5×10 ストラップ 名古屋の通販 by や

嵐 ARASHI 公式グッズ ARASHI Anniversary Tour 5×10 会場限定チャーム付ストラップ 国立

嵐 - ARASHI Anniversary Tour 5×10 ストラップ 名古屋の通販 by や

嵐 ストラップ ARASHI Anniversary Tour 5×20 - その他

嵐 - 嵐【5×10】コンサートグッズ 会場限定 チャーム付きストラップ

Amazon.co.jp: 嵐 ARASHI 公式グッズ ARASHI Anniversary Tour 5×10

新品 嵐 会場限定ストラップ グリーン 緑 ARASHI Anniversary Tour 5×10 福岡 ★ 松本潤 櫻井翔 大野智 相葉雅紀 二宮和也 グッズ | TNカンパニー 楽天市場店

嵐 5×10 ライブストラップ - クリアファイル

嵐 ARASHI Anniversary Tour 5×10 会場限定チャーム付きストラップ

嵐 Anniversaryツアー 5×10 会場限定ストラップ 赤|Yahoo!フリマ(旧

嵐 ARASHI Anniversary Tour 5×10 会場限定チャーム 名古屋ドーム

嵐 会場限定ストラップ ナゴヤドームver.(オレンジ) 「ARASHI Anniversary Tour 5×10」

Amazon.co.jp: 嵐 ARASHI 公式グッズ ARASHI Anniversary Tour 5×10

嵐 ARASHI Anniversary Tour 5×10 会場限定チャーム付きストラップ

嵐 5×10 ライブストラップ - クリアファイル

新品・未使用品 嵐 ARASHI Anniversary Tour 5×20 会場限定 チャーム

Amazon.co.jp: 嵐 ARASHI 公式グッズ ARASHI Anniversary Tour 5×10

2024年最新】嵐 グッズ チャーム5 10の人気アイテム - メルカリ

嵐 東京会場限定チャーム ARASHI Anniversary Tour 5×… - その他

嵐 公式グッズ 5×10 会場限定チャーム - アイドル

嵐AnniversaryTour5×10会場限定チャーム緑 - アイドル

嵐 ARASHI Anniversary Tour 5×10 会場限定チャーム付きストラップ

嵐 会場限定チャーム ARASHI Anniversary Tour 5×10 - アイドル

嵐 5×10 チャーム - キャラクターグッズ

嵐 5×10 ライブストラップ - クリアファイル

嵐 ARASHI Anniversary Tour 5×10 会場限定チャーム 名古屋ドーム

2024年最新】嵐 ARASHI Anniversary Tour 5X10の人気アイテム - メルカリ

駿河屋 - 【買取】嵐 会場限定ストラップ 東京ドームver.(ピンク

嵐 - ARASHI Anniversary Tour 5×10 ストラップ 名古屋の通販 by や

2024年最新】嵐 ARASHI Anniversary Tour 5X10の人気アイテム - メルカリ

嵐 ARASHI Anniversary Tour 5×10 会場限定チャーム 名古屋ドーム

嵐 名古屋 チャームの通販 1,000点以上 | フリマアプリ ラクマ

嵐 5×10 ライブストラップ - クリアファイル

Amazon.co.jp: 嵐 ARASHI Anniversary Tour 5×10 公式グッズ チャーム

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています